LiveTracking MES Platform

Real-Time Production Monitoring

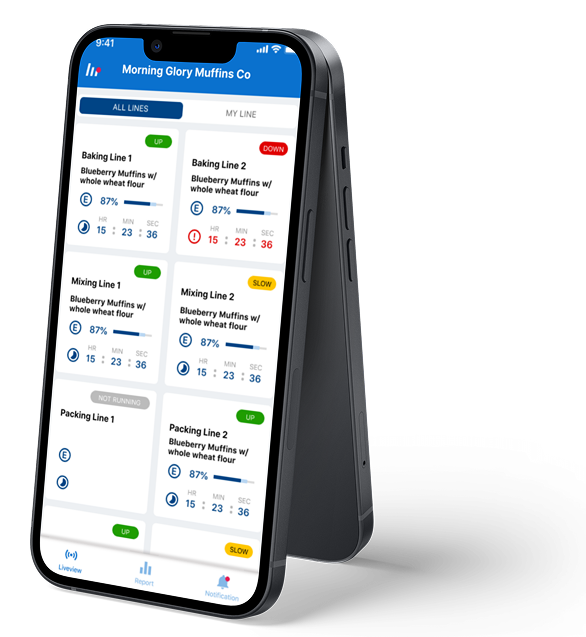

With LiveTracking’s real-time dashboards and notifications, plant managers can quickly identify bottlenecks and take corrective action to enhance operational efficiency.

What is LiveTracking MES?

LiveTracking captures critical metrics like OEE, speed, and downtime directly from the factory floor. With web reports and mobile alerts, you can respond to inefficiencies instantly and keep production running smoothly.

Make Data-Driven Decisions

in Real-Time

With LiveTracking’s real-time dashboards and notifications, plant managers can quickly identify bottlenecks and take corrective action to enhance operational efficiency.

LiveTracking does this by measuring the following KPIs:

- Overall Equipment Effectiveness (OEE)

- Categorized Downtimes including Short Stops

- Waste and Rework

- Line speed

- Headcount

Improve Efficiency with Actionable Insights

Our MES system provides live metrics on waste, rework, and performance, enabling data-backed decisions that boost productivity and help you meet production goals faster.

Learn How to Drive Decisions and Behaviours on The Shop Floor

- Scoreboards

- Live Reports

- Trend Reports

- Data Storage and Security

- PowrBi and Excel Connectivity

- Easy to Install Hardware

Key Benefits for Food & Beverage Manufacturers

Optimize Performance, Minimize Downtime, and

Maximize Efficiency with Real-Time Insights

Downtime Categorization and Reporting

LiveTracking automatically categorizes downtime into planned and unplanned events, helping manufacturers identify root causes and improve equipment utilization with accurate data.

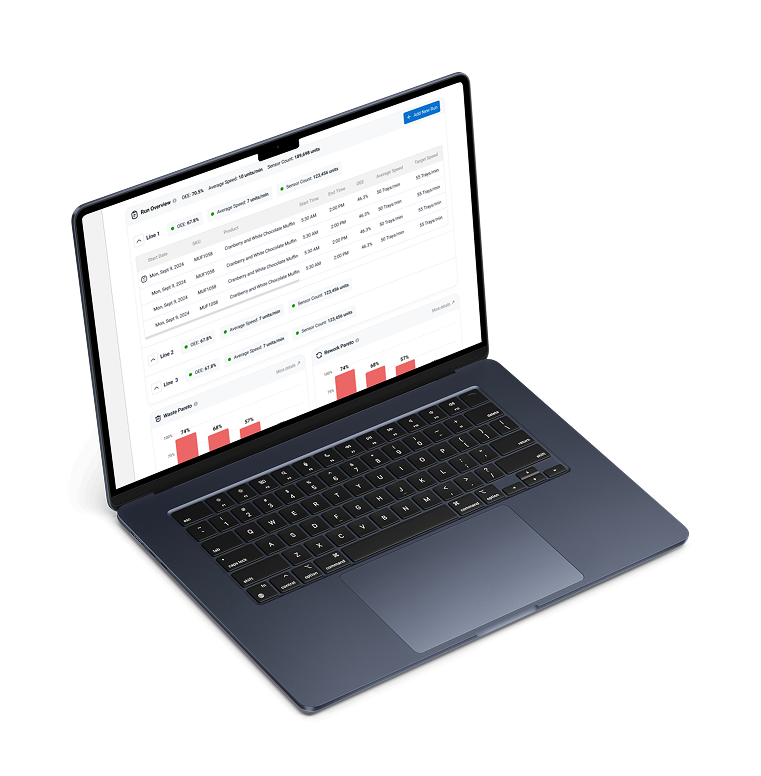

Shift, SKU, and Product-Level Reporting

Understand inefficiencies across shifts or product lines with LiveTracking’s robust analytics tools. From SKU-level tracking to product-specific metrics, gain insights that drive improvements.

Waste and Rework Paretos

LiveTracking’s waste/rework paretos visualize the primary contributors to defects, enabling manufacturers to focus on corrective actions that reduce costs and improve quality.

Enhanced Utilization and Performance Metrics

LiveTracking provides real-time comparisons of planned vs. actual usage, helping you identify underperforming equipment and streamline production schedules.

Fast-Track MES Implementation

LiveTracking deploys seamlessly, enabling real-time data capture almost instantly. Say goodbye to long implementation timelines with our plug-and-play hardware.

More Features

Learn How to Drive Decisions and Behaviours on The Shop Floor

Reduce Unplanned Downtime with MES Software Insights

LiveTracking automatically categorizes downtime into planned and unplanned events, helping manufacturers identify root causes and improve equipment utilization with accurate data.

Streamline Maintenance and Reduce Delays

By tracking downtime at the source, LiveTracking empowers you to prioritize maintenance tasks and prevent unnecessary operational delays, maximizing productivity.

Real-Time Downtime Insights for Smarter Decisions

Break down downtime metrics by equipment failure, operator delays, and more. Our MES software ensures you’re always one step ahead in keeping production on track.

Real-Time Data Analytics for Product Optimization

Understand inefficiencies across shifts or product lines with LiveTracking’s robust analytics tools. From SKU-level tracking to product-specific metrics, gain insights that drive improvements.

Optimize Performance at Every Level

Dive deep into shift patterns and product data to identify areas for improvement. With LiveTracking, you can target specific inefficiencies and align processes for better results.

Data-Driven Solutions for Improved Output

Use granular data to analyze production bottlenecks by shift, SKU, or category. Our advanced MES software ensures optimal resource allocation and enhanced production flow.

Optimize Manufacturing Processes with Real-Time Paretos

LiveTracking’s waste/rework paretos visualize the primary contributors to defects, enabling manufacturers to focus on corrective actions that reduce costs and improve quality.

Drive Quality with Actionable Data

Pinpoint inefficiencies and quality issues in real-time. Our system provides detailed paretos to help manufacturers eliminate waste and meet high-quality standards.

Boost Profits Through Waste Reduction

Minimize waste and enhance profitability with LiveTracking’s advanced analytics. Real-time waste/rework data ensures your production line stays lean and efficient.

Track and Compare Planned vs. Actual Production Usage

LiveTracking provides real-time comparisons of planned vs. actual usage, helping you identify underperforming equipment and streamline production schedules.

Minimize Downtime with Smart Alerts

Our MES software tracks utilization metrics down to the second, empowering you to reduce idle time and improve throughput on every production line.

Optimize Production with Automated Reports

Understand capacity utilization like never before. LiveTracking’s metrics help manufacturers fine-tune production schedules and maximize operational efficiency.

MES for Manufacturers: Fast, Simple, and Effective

LiveTracking deploys seamlessly, enabling real-time data capture almost instantly. Say goodbye to long implementation timelines with our plug-and-play hardware.

Experience Minimal Downtime During Installation

Our fast-track setup ensures manufacturers can start monitoring and optimizing operations without significant disruptions to the production line.

Accelerate ROI with Rapid MES Implementation

With a quick deployment process, LiveTracking helps manufacturers achieve ROI faster by providing actionable insights and real-time data from day one.

Live Data for Smarter Decision-Making

Improve quality control in food processing with MES systems designed for compliance and precision.

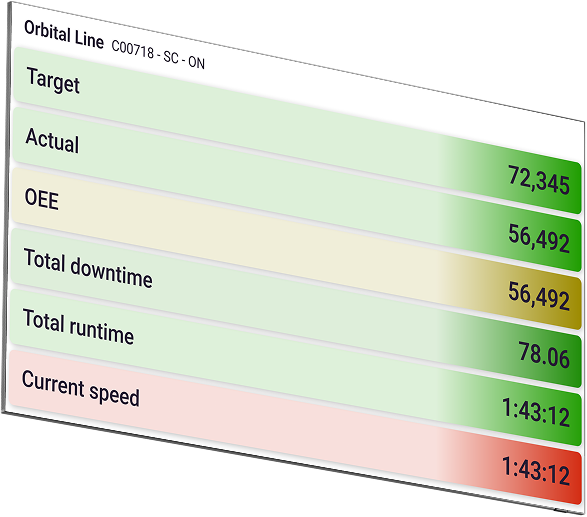

Scoreboards

One of the most powerful ways to leverage LiveTracking’s real-time data capture and reporting capabilities is with our shop-floor scoreboards. Our scoreboards have easy to configure KPIs and layout display options. Plus, they are optimized for nearly any display resolution.

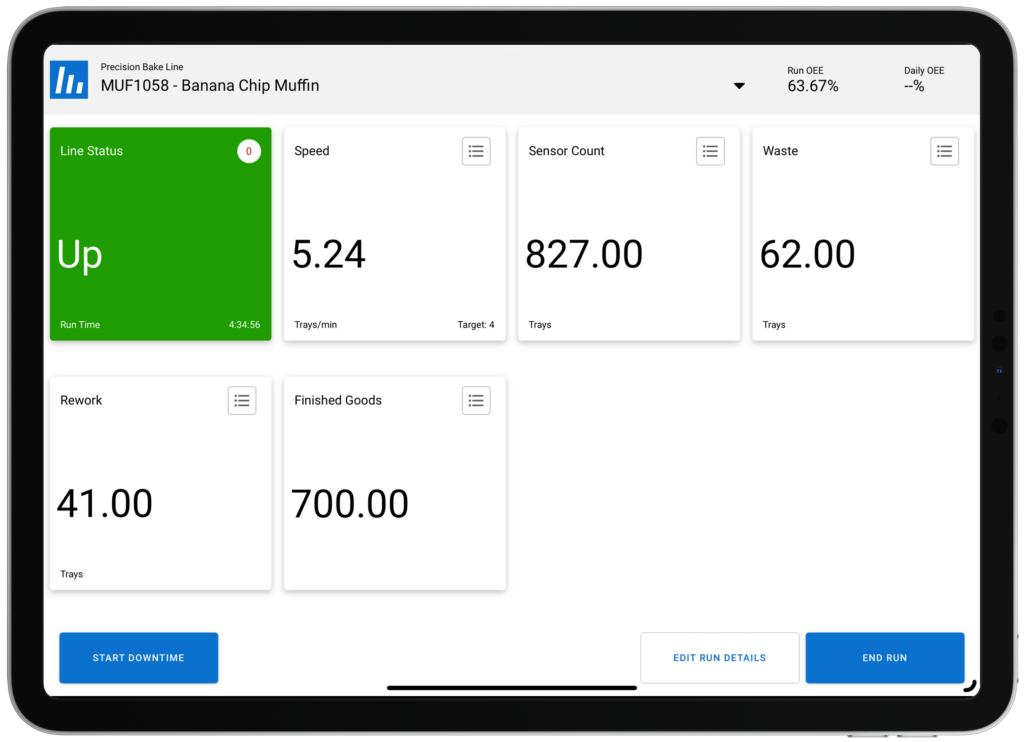

Live Reports

Our reports show connections between data, performance, and the shop floor by providing a real-time display of actual units produced, OEE, downtime, runtime, and manufacture speed. This gives a live and easy view to the shop floor’s current state and how you’re doing during the day.

Trend Reports

Know your shop floor’s top KPIs with consolidated trend reports that are easily accessible with LiveTracking. These monthly or quarterly trend reports can be accessed by Operations Management to understand the overall performance of your lines & identify the specific opportunities for improvement.

Data Storage and Security

LiveTracking leverages the power of the cloud for unlimited storage, real-time performance, and superior data processing power that is built with a secure, high-performing, resilient, and efficient infrastructure from AWS. This guards identity and access, protects data, secures applications, and meets your compliance objectives.

PowerBI and Excel connectivity

With embedded Power BI and Excel connectivity, LiveTracking gives you an extensive export function that allows customer-designed reports and dashboards. This also allows you to easily access, gather, shape, analyze, and explore your key business data and get broad data analytics and visualization capabilities—all in less time.

Easy to install hardware

LiveTracking can be set up in a matter of hours or days, not weeks or months. You can mount them in key locations of the shop floor to automatically track downtime, line speed, and output. Once sensors are installed and KPIs are configured, your facility will digitize and provide you with real-time data by the end of the day.

"We use LiveTracking to drive continuous improved behaviours on the shop floor"

Ippolito Fruit & Produce Ltd